Cobra Combi Tuning

Getting these things running perfectly can be a challenge. Like other 2-stroke motors, they may require re-tuning when major changes occur in operating altitude or temperature or after an overhaul.

The Cobra Combi features a very unique design, including a 185cc engine mounted upside down and a “piston firing against another piston” that makes it difficult to check compression or gauge condition without a teardown.

Before you send your unit in for service, try a tune-up first. We can supply field service kits and obsolete parts for Cobra Combi and Redhawk drills. For current parts or new sales, check out Crowder Supply.

Important Note: We recommend NOT messing with the carburetor settings before you have tried replacing the air filter and spark plug and installing new carburetor gaskets. We can supply a tune-up kit for about $100.

Tools Required:

- 10mm nut driver or flat-head screwdriver to remove air cleaner cover

- 1/8″ flat-head screwdriver

- Small piece of 1/8″ ID vacuum hose to fit over end of screwdriver

- Can of 50:1 pre-mix gasoline.

Preparation

- Make sure the unit has a new spark plug and that the exhaust needle has been cleaned per the manual.

- Fill the tank with fresh 50:1 fuel. Initial tuning should always be performed with store-bought 2-stroke fuel to eliminate variation in pump gas and mix ratios.

- Install a dirt tamper or other tool on your drill.

- Start the unit and allow it to warm up for 2-3 minutes. Starting is often easier with the drill lever in the middle position.

- Shut down the drill and remove the top and air cleaner element.

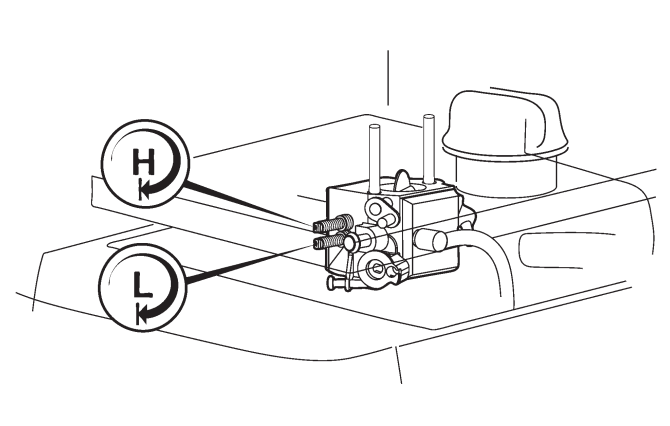

- Locate the mixture screws using the diagrams below.

Tuning

- Start the unit up again. Adjust the choke to keep it running as needed. Tuning works best when engine is warm!

- Set the drill lever to the up position if using a tamper or jackhammer bit. Set it to down if drilling rock or concrete.

- With the unit running and warm, adjust the idle (L) mixture screw for smooth operation, using the diagram above. The starting settings are as follows:

- Idle (low-speed mixture screw on bottom) should be screwed down all the way and backed out 720 degrees

- Move the choke dial to the half-way point. If the engine idles better or stays running when it did not before, you need to make the mixture richer.

- Adjustments should be carried out 1/8 turn at a time. Turning the mixture screw counter-clockwise adds fuel.

- Turn the choke to normal run position and re-check after each adjustment. Test the drill and repeat procedure as needed.

- Repeat the process with the high-speed (H) mixture screw. The starting settings are as follows:

- Full throttle (high-speed mixture screw on top) should be screwed down all the way and back out 1040 degrees

- Move the choke dial to the half-way point. If the engine idles better or stays running when it did not before, you need to make the mixture richer.

- Adjustments should be carried out 1/8 turn at a time. Turning the mixture screw counter-clockwise adds fuel.

- Turn the choke to normal run position and re-check after each adjustment. Test the drill and repeat procedure as needed

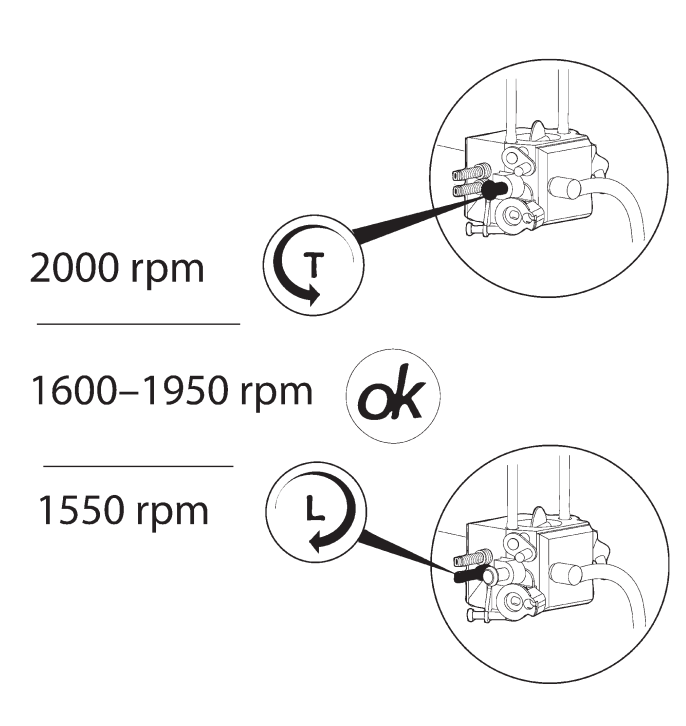

- Adjust the idle speed and throttle speed as needed. using the diagram below.

- Run the drill and check that it does not die at idle or full speed. If engine dies at full throttle, even after several iterations of mixture tuning and a full warm-up, you may need to turn the throttle stop down 1/8 turn at a time until it operates reliably.

- Be sure to apply downward pressure with the handles during final testing. The units needs to be performing work to really test out the fuel settings.

- Reassemble the unit and verify operation.

Troubleshooting Tips

| Problem | Steps to take |

| Unit will not start | Pour a small amount of fuel into carb and attempt to start. If it runs, see steps below. If it does not, check spark plug condition and test for ignition spark . Make sure the red kill switch is set to the “ON” position (towards operator). Consider replacing carburator diaphragms. |

| Unit starts but dies when throttle is engaged | Make sure unit is fully warmed up and try again. Check fuel line for cracks or kinks. Check air filter. Disconnect fuel line from carb, open fuel tank cap and blow into tube. If any resistance, replace fuel filter and re-test. It should feel about like blowing through a straw into a cup of water. Try running unit at partial choke. Replace carb diaphragms. Try tuning procedure and re-test. |

| Fuel filter and line OK, but unit runs poorly. | Replace spark plug. Check air filter. Refill tank with fresh 50:1 pre-mix fuel. Clean the exhaust needle, per operation manual. Complete the tuning procedure and re-test. Replace carb diaphragms, especially if unit has been sitting or ethanol gas is used. |

| Unit does not hit hard or barely runs, even after troubleshooting and tuning. | Consider sending in for an overhaul if above steps do not help. Excessive wear will show up in the form of a worn-out drill check and low compression. Check for chuck wear with a 7/8″ chuck gauge. If the chuck is loose, there is a very good chance the rest of the unit is ready for an overhaul. Replace carb diaphragms if not already done. |

| Unit will not draw fuel from the tank, but will run if a bulb full of fuel is attached to carb and squeezed | Check for kinked or perforated fuel lines. Check for a blown check valve. This can happen if the carb was cleaned aggressively with compressed air or pressurized cleaner. To test, attach an automotive vacuum hand pump to the fuel input and see if it can hold back a vacuum. Blown check valves can be replaced, but it is a somewhat tricky and specialized job. |

Additional Tips and Resources

- Never replace the carburetor on this unit with an aftermarket part. Unlike tools such as chainsaws, there are no direct replacements available. The Cobra Combi uses a 185cc engine, and very few small engine carburetors are up to to the task. Rebuild and tune the unit you have!

- Drills that have been sitting for a long period of time often have bad carburetor diaphragms or gummed up internal parts. We can sell you the correct overhaul kit. An ultrasonic cleaner is the best way to clean out dirty carbs. Do not use compressed air as the check valve can be damaged.

- These carburetors are also used on light aircraft. An advanced tutorial on fine-tuning these carbs carbs can be found at the here.